What is hologram

Holograms, holographic seals and imprints are used more and more for the authorization of documents, declaring of authenticity of the products and also for sealing those parts of the products in which it is needed to see whether the openning was unauthorized. Holograms are becoming a very sought out and effective way of prevention from falsification and misuse of anything that can be protected by a hologram. The hologram defines the highest standard of security and adds the profesionality and originality to the product. Generally, there are many ways to produce the holographic picture and also different ways to use it, including original purpose to save the data on the optic carriers.Obviously not all expensive ways of producing the holograms, originated from the research in the laboratories, are used for the production of holograms, because it is not a technology used for saving the data. What is in common for all holograms is a high diversity of graphic output, which outclasses the options of classic printing in multiple ways. Thanks to this characteristics it is very hard to eventually falsify and it is also one of the necessary conditions for the holographic effect. Above all that, high diversity allows to put security signs on the hologram about which the user will not know and they will be controlable only by special appliances or maybe only in the lab. This is for example microtext or micrographics, which can be, in addition to your wish, produced the way that it will be only readable under the laser light.

All holograms that are used for above stated purposes are, in fact, made of a specific film with purposedly deformated surface. The picture itself is created thanks to the refraction and intereferentions according to exact calculations of microscopic deformations. A mask for these nicks is made according to records given by the customer, that means according to any graphical data. Even if the pattern for the hologram production is in 2D, the final picture can be seen as 3D thanks to specific characteristics of the holographic display. We are able to produce 3D holograms as well, but the pattern for that must be graphically more complicated. that is the reason why most of our customers prefer the holograms made from 2D pattern. For self-adhesive stickers you can choose from 2 types of films - silver or golden.

Apart from the methods of hologram production stated above there are few others technologies, but they need a more complicated way to prepare the produciton and higher costs for the seal produciton. If you are interested in other kinds of holograms, feel free to contact us!

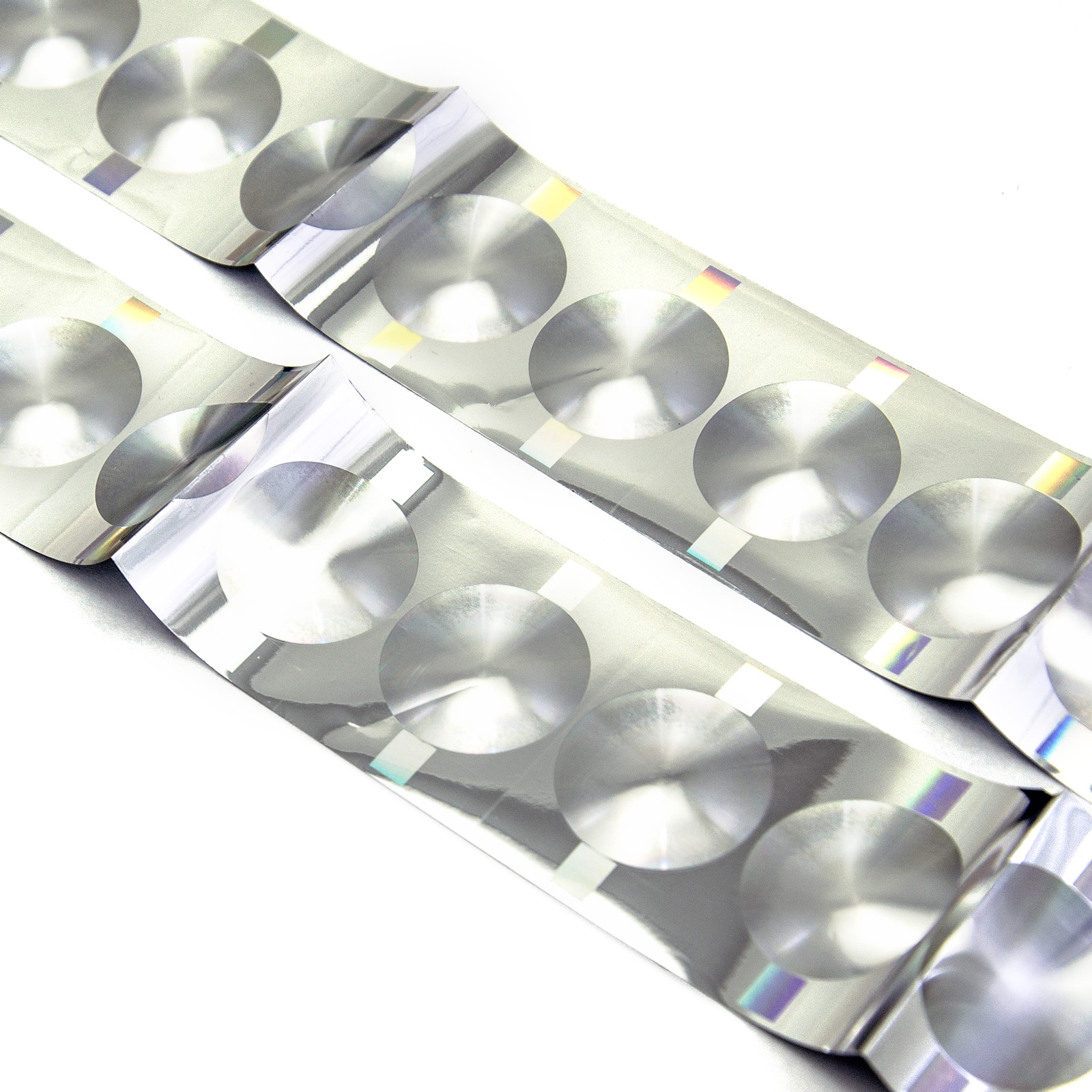

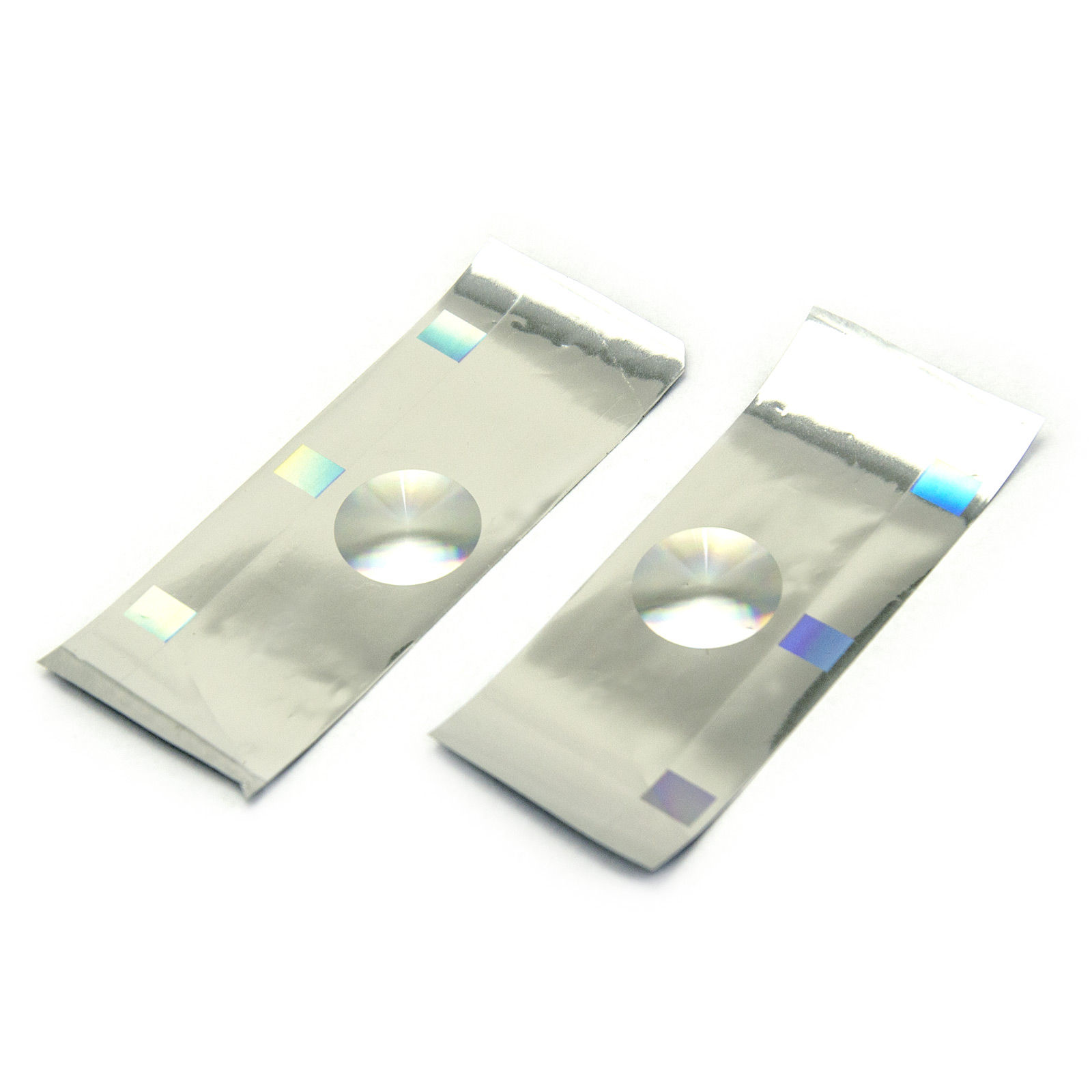

Every one of the techniques stated above can apply to 2 types of self-adhesive medias: the first one is a very thin smooth film which has a metallic layer on its basal part - that can be golden or silver, it depend on your choice. The holographic picture carrier is that exact metallic layer that has a holographic motive burned into while produced. The film defines mechanical strength of the whole seal and it is also used as a protection of the holographic layer from mechanical damage. There is a layer of glue on its basal part, just as it is on every ordinary self-adhesive sticker. When you try to remove the seal from its place, it gets damaged. The measure of damage depends on the surface that it is sticked to. Basically, it is impossible to remove the hologram and stick it to another place without damaging it, you just have to make sure that the surface you are placing the hologram on, is not greasy. The second type of media is so called destructive Void evident film. This self-adhesive medium is produced the way that any attempt to remove the seal would be clearly seen right away. The stamp gets evidently damaged. The seal is not removable neither by heating the film e.g. by a hot-flue gun, as it is possible with other self-adhesive security stickers. When trying to remove it, part of the holographic layer disjoins from the film, another part stays sticked to the surface and another one to the film. That part which stays sticked to the film is given by a chosen pattern media. There are 4 types of media produced in advance, which leave a clearly readable text "VOID", "ORIGINAL" or "Cancelled" or a regular graphical motive similar to honeycombs and leave this text or motive on both the surface and the film after removing. This method is used in all places which need to be prevented from unauthorized entries to prohibited areas like the inner parts of electrical systems, sealed documents, boxes for transportation of valuable things, doors of baggage areas sealed with bigger seals, etc.

The size of particular self-adhesive stickers is not limited and will always be correspondent with your requests. Practically, it is always possible to produce holographic seals with diameter of 3mm to stick to the tops of the screws, just as it is possible to produce a hologram of a size A4. All stamps will be cut according to your requested sizes and will be delivered in sheets to size A4 or in rolls. They will be cut according to the shape you choose when designing a graphical project of the seal. Basically, it is possible to produce a seal of any size, you just need to keep in mind that you want them to be easily transported to the object you want to label. For this reason we recommend you choose from these shapes: a circle, an ellipse, an oval, a square or a rectangle, a square or a rectangle with round corners, triangle, n-angle and similar periodic formations.

If by facts stated above you have an idea of how should a proper holographic seal fulfilling your requirements look like, it is needed to create its digital pattern. If you have an option to use any of the vectorial graphical editors (we recommend Corel Draw) and you have enough experience for creating the pattern, you can send it to us directly with the vectorial data. Of course, it would be our pleasure to prepare a pattern ourselves, using your specifics. In case of simpler motives all that is needed is their description in words, with exact parameters, according to which we will email you a graphical projection, in some case more of them. After its correction and approbation of the final graphical projection it is possible to start the production of self-adhesive stickers right away. In case you need seals of a small size, we highly recommend to print these seals during the projection by a regular printer in its exact parameters. In many cases the amount of textual and graphical information exceeds the options of a small format a bit and the result of this is a very small area that is overfull with information easily readable only by a microscope. This fact is not visible enough mostly when your projection is shown at 24'' monitor in graphical editor.

Applying customer Holographic foil destructive or self-adhesive hologram labels destructive or disruptive element films I obtain the object, which is not possible by any conventional polygraphic methods successfully reproduce. If provided with a printed custom holograms, as well as printed matter that can not be faithfully reproduced. This is one of the major benefits to using hologram labels and stickers, which the list begins.

Holographic self-adhesive stickers are produced by pressing to a plastic electroplated or transparent film. Acrylate gule is then put on the basal layer (metallic layer) of the sticker. Holographic etiquette therefore has 3 layers, and characteristics of these layers can be chosen according to your needs and intended application of this self-adhesive sticker.

Top layer of holographic etiquette is made of a plastic film which is very thin and translucent. This film for printing of self-adhesive sticker can be made of OPP, PVC or PET materials. The most used material for holographic stickers is PET (polyethylene terephthalate) in almost amorphic form, which guarantees high transparency. All holographic etiquettes are normally produced on the basis of a PET film because this material fulfils all required characteristics almost perfectly. One of the fancied characteristics is high resistance against wide variety of chemicals, mechanical strength, extremely high impenetrability of liquids and gases, low thermal dilatation and resistance against high temperatures which allows the lamination of holographic seals and also impress in laser printer (the melting point of PET is around 267 °C). Its alternative can be an oriented polypropylene which is used mostly as a wrapping material for its better pull strength. Therefore it is no used for a production of self-adhesive stickers but it is rolled to rolls as feature-length wrapping materials.Of course there are customer’s holographic motives all over the sheet which are repeating in cycles. There is no gluing at holographic OPP wrapping films. PVC joined with holographic printing can be used for special applications like a wrapping material for groceries (instant contact with the groceries). PVC film is known for its high mechanical expansion and therefore has to be combined with layers of other materials like OPP or PET to be suitable for a production of the holographic film.This kind of film can then be also used for a production of holographic periodical patterns used for wrapping.

Another optional parameter of a load-bearing film of holograms is thickness of the film. This information is not important for standard applications of the self-adhesive stickers and holograms are printed to PET film with the thickness of 67 microns. For your special applications of etiquettes or wrapping materials you have an option of choosing the thickness of 20 microns. The price will be calculated individually if a customer chooses his own thickness. All prices listed at our website are calculated with the thickness of 67 microns of a PET film.

The middle layer out of all 3 layers of the holographic self-adhesive sticker “sandwich” is a very thin metallic layer into which a holographic impression alone is transacted. Exactly this layer is a load-bearing medium for rainbowlike passages creating pictures that are in your pre design. Top layer in a form of a plastic film gives mechanical strength to the sticker and protects the metallic layer from damaging.

Most commonly used is an aluminium layer which gives holograms a typical appearance of silver reflecting areas with rainbow like tones. Silver colour of the base offers the most plastic, the most colourful and the most outstanding effects even when the light is very bad. The most perfect effects are achievable at the full daylight.

Apart from the most famous silver colour of holograms you can also choose from other colours just so it suits your purposes. The colour of a load-bearing film stays unchanged and a colour-bearing part according to your choice will be borne by a layer of metal into which the hologram is printed. Apart from silver, amid commonly used colours belongs also golden, and for these most commonly used colours we have prices calculated here at our websites. You also have an option of a blue, green, yellow, red colour... A price for these colours of medias will be calculated individually with a concrete order.

After physical production of holographic self-adhesive sticker – pressing of graphical items to load-bearing metallic film- the hologram itself is almost finished. It will contain as many layers as the method of its production allows. In this phase of production can, however, be used another method which gives your predesign another layer or can be used as a very effective creative item. In another layer it is possible to define the transparencies. From a digital processing of a picture we deal with one bite alpha channel. At a completed load-bearing metallic film with holographic relief, a photosensitive layer is applied. This layer is lighten through a template produced on a base of graphical layout of demetallizing layer, the photosensitive surface is then chemically initiated to wash away the coping film from unlighted areas. After that, the holographic layer is oiled in an acid which outlines the uncovered areas of load-bearing layer. Holographic impression which should be visible are not influenced by this process, however, other areas are outlined and therefore stay transparent.

This method is usable no matter of previous preparation of hologram (single layered, two layered, with master...) and can also be used for numbering or text describing. This layer is always greatly visible and readable. By this method it is also possible to create translucent windows e.g. for visualizing of series numbers at which will the securing self-adhesive sticker be stick on. Demetallization is also used for a production of transparent holograms which should not cover the pictures at which they are stick on. Last but not least it is a method which allows to create a self-adhesive sticker with arbitrarily shaped edges – e.g. in a shape of a seal or a leaf with burnt edges.

After hologram is pressed into metallic film on a load-bearing plastic film, the etiquette is finished. But to make a self-adhesive sticker, another layer has to be put on – a glue. On a basal metallic layer a very thin layer of a permanent transparent acrylic glue is applied.

An option of choice when designing your own self-adhesive stickers is in this layer represented by Tamper-evident or Void-evident technology. In these types of self-adhesive stickers, the glue is not applied on a whole area of hologram, but through the template with a specific pattern. When the sticker is removed, in those areas which were not under-glued, the metallic film does not divide from a plastic film and the graphics that was used for a production of the template will not get visible. Stickers produced this way show increased probability of unauthorized unsticking and react by a specific damaging of load-bearing metallic layer – exposing the words “VOID”, “ORIGINAL”, “Cancelled” or a regular graphical emblem (depending on a type of chosen pattern medium). It is clear right away that the hologram was unsticked even if just a little bit. Attempts to stick it on again will not change anything about the visibility of exposed words. This technology highly increases security value of a seal because even if the seal was unsticked from a badly ungreased or a rough surface by potential violators, it will be changed by exposing the greatly visible words for good.

When ordering tamper evident self-adhesive stickers you can choose from above stated words or you can create your own graphics made of words or emblems. The choice of user’s pattern will, of course be financially more demanding than general usage of patterns from our menu.

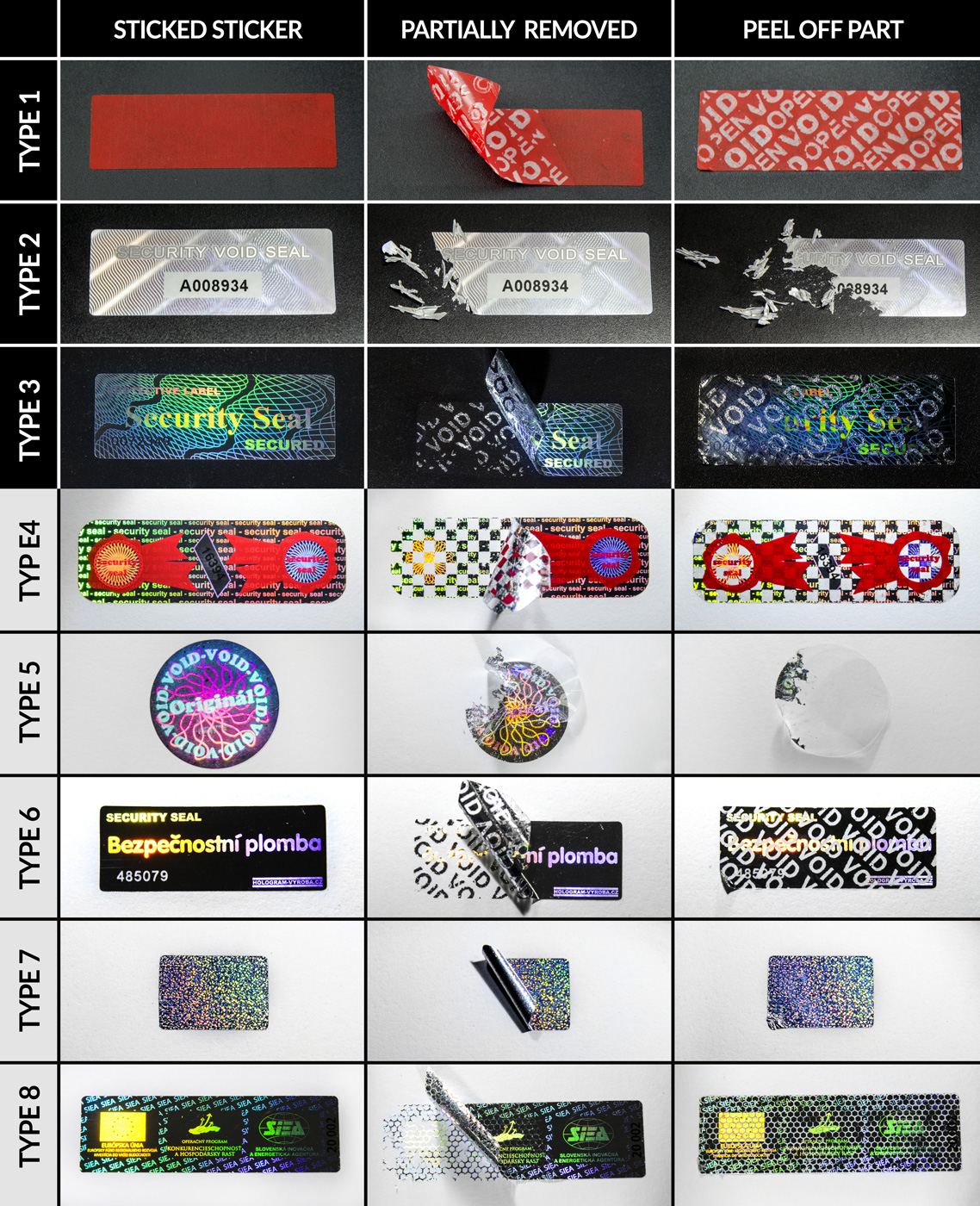

TYPE 1 - Non-residual sticker with destructive VOID surface (reinforced adhesive)

TYPE 2 - Vinyl sticker with hologram layer and destructive surface (reinforced adhesive)

TYPE 3 - Two-layer hologram sticker with destructive VOID surface (reinforced adhesive)

TYPE 4 - Two-layer hologram sticker with screen printing and square VOID surface

TYPE 5 - Two-layer hologram sticker with standard safety surface

TYPE 6 - One-layer hologram sticker with destructive VOID surface

TYPE 7 - Master hologram sticker with no safety layer with non-residual surface

TYPE 8 - Two-layer hologram sticker with HoneyComb destructive surface

We have tried a strengthened layer of glue for holographic etiquettes intended for more problematic (rough) surfaces. You can now use this option even in your predesigns of self-adhesive sticker. You can try the paster with a higher gluing layer yourself, directly for your application. You can find it in in-store stickers - Flip-flop multi layered holographic seal. More information about adherence of the sticker is written in the next article.

Normally, holographic stickers are made on a very thin PVC film, its thickness is about 30 micrometers. It is intended to produce a self-adhesive sticker that would be as thin as possible and therefore would not disrupt the surface on which it is stick on. This way it will not create a disruptive relief and its edges will not be too high. As the PVC film is thinner, the sticker is more resistible against intended and unintended unsticking – with this extremely low thickness it is not possible to unstuck the sticker with the nail or a razor and it gets instantly and visibly damaged. With regard to determining holographic self-adhesive materials is impossibility of unsticking of the sticker a very important and watched parameter. An important role here plays the layer of glue which is applied on the basal side.

A layer of glue that is used as a basal part of holographic self-adhesive materials cannot increase a profile of the paster because of the reasons stated above and therefore this layer is extremely thin. For these applications ahigh quality hydro gel glue is used.

To get an expected adherence to the surface after sticking on the sticker, to keep all these production methods is not enough. A phase of application – actual sticking of the sticker to an intended place - is as important as these methods. This procedure is done usually by you. Because of that, please, keep these two important things in mind:

Apart from cleanliness of the surface, its very structure is important. It does not really matter whether the surface is absorbent or not. Critical is whether the surface is smooth or rough. Glazed metallic surfaces chrome and glazed parts, smooth plastic or glassy surfaces create absolutely ideal place for sticking on the hologram because here it will be stick by its whole area. From places like these it is sure that it cannot be taken off without damaging. In case of rough surfaces the constant of adherence will, unfortunately decrease. That, however, does not mean holograms cannot be stick on these surfaces because thanks to quality glue there is great back-up. As the surface is rougher, demands for ungreasing it increase. From microscopic point of view rough surface represents some kind of a hilly land and distinctly decreases the area which will be used to stick the sticker on with a glue. For the layer of glue is very thin, the area used for sticking the stickers is only tops of those “hills”. If it is possible, we commend to glue an object or a product in a place that will be structurally most suitable for the best adherence (in a part of the most suitable material). A big problem could be an unlacquered wooden surface – here it is necessary to do practical testing by sticking the sticker for the surface of wood can be scapppled many ways with different degrees of smoothness. Another option of resolving this is using increased layer of glue. You can use this option when pre designing and ordering the self-adhesive sticker according to Your design.

If you are planning to stick the sticker on a product that could have a problematic surface (according to what is written above), we recommend you to order samples first and try their sticking to the surface. Do not forget to order order a Flip-flop holographic seal along with the samples.This seal has a much higher layer of glue so its adherence to rough surfaces is much better. You can ask for a strengthened layer of glue while ordering the self-adhesive stickers according to Your design.

Holographic master is a name for original pressing forms for reproduction of holograms it is a deck into which an exact mathematically generated picture according to graphical pre designs of hologram is burnt by laser. If you need to seal a lot of copies, also copies of the master have to be made. For sealing is normally used nickel stamping die – a nickel deck with a “printed” picture of a hologram. There are many types of holograms and in connection with that also multiple ways of pressing die production. The master can be produced by burnout with help of a coherent collimated laser light radiation directly on a glazed metallic deck. By this process a positive pressing die is directly produced. A more used method of using laser radiants with much smaller capacities and therefore cheaper appliance with using of the photo path – a glassy deck with a layer of photosensitive material, which is brought up by lighted/unlighted (positive/negative photo material) and this deck is lightened instead of a metallic deck. A master produced like this cannot be used for impression of holograms on cylinder presses and therefore a metallic copy of it has to be made. A glassy deck with holographic pattern is silvered by silver vapours. Consequently produced conductive layers are then used either for direct galvanizing by a nickel or for production of copies, with a help of so called electronic forming which results in a nickel deck for impression. As many dies can be created as its needed for a precise production according to desires of a customer.

Guilloche item is another graphic security appliance which you can use in your predesign of a hologram. It consists of thin corrugated lines which create ornamental patterns (rosaces) for many known from their childhood game Inspiro. Complicated geometrical formations of guilloches are suitable for securing and decorating too. Typical usage is securing most of the state documents of high importance nad mainly for preventing bank notes from falsifying. Guilloche strings can be found in ID cards, driving licences, arms licencs, passports, technical cards, highway stamps, reports, trade licences and of course, on every paper means of payment. Specially paper money and bankable papers have been guilloched by many applications. Long time ago it was necessary to use resourceful mechanical machines using a similar principle to above mentioned Inspiro to create a guilloche. They carved thin corrugated lines into a metallic deck, creating compliacted, multiple times crossing and immutable cyclic geometrical formation according to a mechanical setting of the machine. This stamping die is then used as a printing deck for primer printing of documents and papers that want to be secured. The higher safety level the thinner line, thicker line printing and more crossing used in the pattern.

Guilloche presents a good prevention against falsification by scanning, printing or copying. Individual lines of the geometrical pattern are damaged while scanning and followed-up reproducting and therefore consist of many disjointed points thanks to deficient discernment of scanning and also printing. Todays numerical processing allows fluent and fast predesign of guilloche ornamentts thanks to exact mathematically described curves and preparation for printing in unlimited discernment. The same way of imitation of security picture could be used when falsifying and that is the reason why a software for generating guilloche patterns offers a function of making random mistakes in the structure of the curves. In som e places of the line it turns aside from the matemathically calculated position on purpose and a falsificate will differ in these abnormalities under the microscope. Apart from the function preventing from falsification and copying, a guilloche can have only a decorative function and gives respectability and authenticity to the documents. Above that, graphically unused areas get filled. Decorative patterns are used as a predesign or e.g. frames of graphical items – rosaces.

Design of a hologram or a vinyl self-adhesive sticker with guilloche

If your vectoral graphical appliance allows to create a guilloche pattern, simply blend it into one layer of the predesign. If you want to use guilloche predesign at your order, we offer you our own guilloche ornament as a pattern. The same way we are capable to create ornaments of this type, like a rosace rounded by graphical items added by you. All you need to do is contact us and describe your idea.