Product description

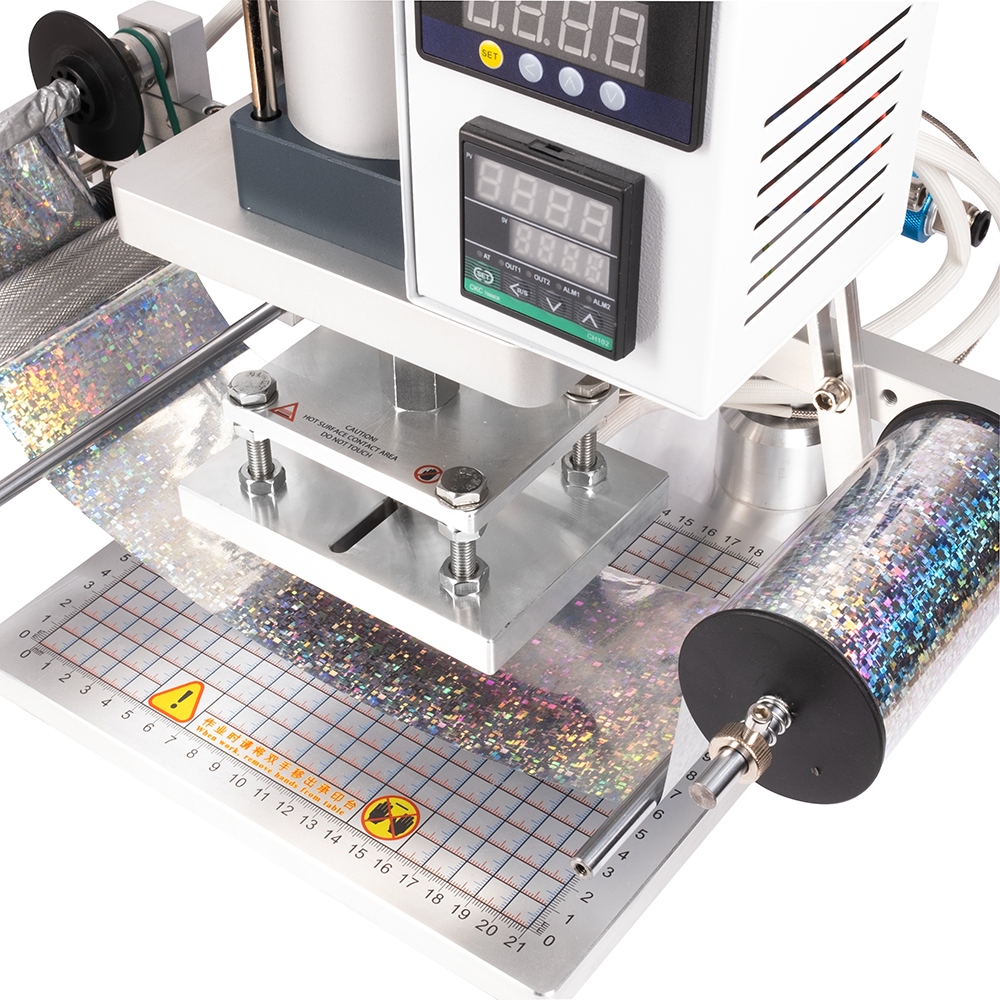

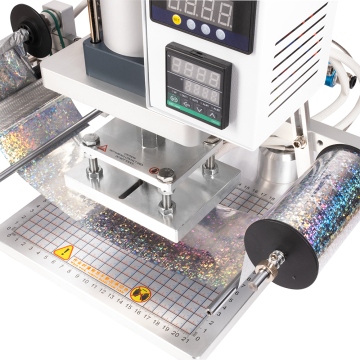

MODEL WT-QS100 isfully automatic, the film unwinding is driven by an electric motor, the pressure piston is pneumatic and driven by compressed air fed into the press via an 8mm air line. The press allows you to set the temperature of heating the plate in the range of 50-350℃, set the time of pressing the plate on the substrate in the range of 0.1-9.9s. The pressure force of 0.4~0.7MPa can be controlled by the air regulator in the back of the press.

In the case of hostamping, a holder with automatic unwinding is provided for the film. The holder can hold a film with a maximum width of 100mm. The head of the press is placed on a height-adjustable stand, which allows the insertion of objects up to 125mm high. The stamping plate itself is made of brass. This brass block is removable from the press - so you can make multiple stamping surfaces that can be easily changed within a single press once it has cooled down - the stamp is held on by a single nut and bolt. Any stamp can be produced up to a maximum stamping area of 100 x 130mm. The level of detail can be very high, it always depends on the material you want to stamp (burn). When it comes to wood, it is preferable to choose larger spacing of individual lines to avoid their fusing (at least 0.5mm). In the case of leather, the lines can be spaced as far apart as 0.25mm, which cannot really limit anyone - see the embossing examples in the product images. The up/down movement of the stamping head is controlled by a pneumatic piston, which guarantees a smooth movement with high and even pressure, ensuring perfect results in thermal stamping and burning. The vertical movement of the piston is 50mm. The whole press is of high quality all-metal and solid construction, which guarantees a long service life of the press and perfect results in marking and burning.

The operation of the press is very simple, to start the hot stamping or burning process, just press the pedal, the rest is taken care of by the press, which is fully automatic.

Examples of use:

Burning into leather - burning logos into leather wallets, belts, bags, purses, covers, thesis covers and diaries.

Burning into wood - wooden gift boxes - cigars, cigarettes, burning logos into boards (worktops, wooden cutting boards), wooden decorative labels, wooden tourist stamps and other wooden gift items with flat surfaces.

Burning into plastic - hot stamping logos into boxes and flat plastic surfaces, sealing all plastic PP/PVC/PE bags, burning logos into plexiglass.

Burning into paper - cardboard (unfolded) boxes, gift bags made of darker paper, cardboard clothing labels and more.

The press requires a compressed air supply from a compressor or air line in addition to a power supply.

The press comes with one custom printed plate, please refer to the "production instructions" section to receive materials for plate production.

The price for the production of another plate is 2500-5500Kč depending on the size, the price is only approximate, for the exact price and delivery date please contact the sales department.

| Weight | 25 kg |

| Press model | WT-QS100 |

| Power supply | 230V/50Hz |

| Power input | 500W |

| Air supply | 8mm inlet, quick coupler |

| Temperature setting | 50-350℃ |

| Press heating | according to temperature 2-4min |

| Pressure setting | 0.4-0.7MPa |

| Pressure length adjustment | 0.1-9,9s |

| Dimension of the plate | 100x130mm |

| Maximum width of hostamp film | 100mm |

| Adjustable height of press head | 10-175mm (must subtract piston movement) |

| Vertical piston movement | 50mm |

| Press dimensions | 385x380x460mm DxHxH |

| Press weight | 22kg |

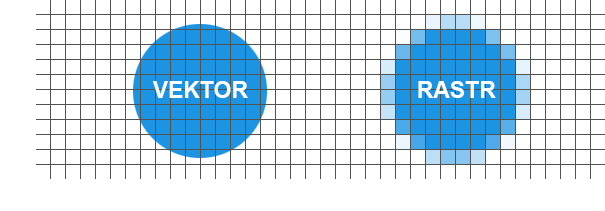

The resulting production base should look like the image below. The black areas are the raised areas that will be fired, the white areas will be milled (they will not be fired). It is recommended that you choose sufficient spacing between the lines according to the material you will be burning into. Although the level of detail can be very high, it always depends on the material you want to emboss (burn into). When it comes to wood, it is preferable to choose larger line spacing to prevent line fusing (at least 0.5mm). For leather, the lines can be spaced less, even 0.25mm apart, which can't really limit anyone - see the embossing examples in the product images

In case you do not have any background materials, you can have custom graphics made by us. The template can then be just a sketch or a text assignment. Our graphic designer has a rich imagination.

Related products

-

R4 Burning die for leather and plastic stamping with custom logo (design)

from 150.393 € / pc.

R4 Burning die for leather and plastic stamping with custom logo (design)

from 150.393 € / pc.

from 122.271 € without VATon order400304Product detail -

R5 Hot stamping – leather, wood and cardboard burner, customer graphic design, 350W

from 456.55 € / pc.

R5 Hot stamping – leather, wood and cardboard burner, customer graphic design, 350W

from 456.55 € / pc.

from 371.179 € without VATon order400375Product detail -

R6 Gas brand stamping device with your own logo design

from 263.188 € / pc.

R6 Gas brand stamping device with your own logo design

from 263.188 € / pc.

from 213.974 € without VATon order400420Product detail

R13 Automatic pneumatic hot stamping press for hot stamping and burning with custom design

The press is not only suitable for thermal stamping / gold printing using special hot-stamp coloured foils, but can also be used for direct burning of texts or graphics into wood and leather.

Thermo-inking, i.e. transferring coloured (gold, silver, holographic foils, monochrome foils) foils using a brass plate, is mainly used for decorating / gilding text and graphics on book covers, invitations, envelopes, wedding invitations, certificates. For burning, the same plate is used with the difference that no foil is used, but only the temperature of the plate is raised in the press by means of the integrated print head heating. In this way it is then possible to burn graphics or texts into, for example, wooden or leather products.