Product description

High-efficient burning (calibration) die with your own design – logo, emblem, graphics or simply text with maximum size of 50x70mms (even smaller). Your motif is custom-molded into brass, and this way made brass stamp is connected to a high-performance solder´s heating element with two massive heaters.

The solder is a full-metal, solid construction, equipped with an industrial temperature control with feedback thanks to the inserted thermocouple inside the heating element. The burner has a thermal regulation from 40°C with the maximum temperature of up to 400°C, which can heat the golden brass stamp up to brown. The grip of the punch is covered by pleasant soft padding. The weight of the burner is just 1.1kg. The power cord is connected from the back in place where the display is. In case of need, it can also be disconnected when requested temperature achieved and can be used for burning without the power cord thanks to high thermal inertia of the heating element. The heating is relatively fast – approx. 2mins.

The stamp temperature is more than enough for leather stamping – for example for burning logo to leather wallets, belts, handbags, it is also ideal for wood stamping - e.g. pallets, wooden gift boxes (cigars, cigarettes etc.), it is suitable for plastics as well, an ideal for original sealing of all plastic bags PP/PVC/PE, also suitable for hot stamping. It is great for cardboard burning, possibly used for game marking and other use.

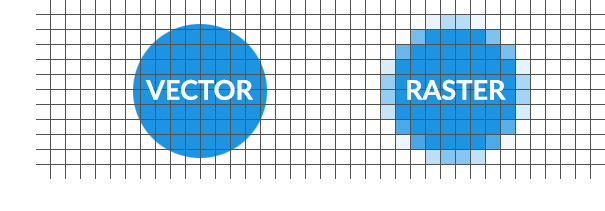

The supplied graphic design, for the stamp production have to be in vector graphics (curves) in *.AI, PDF, EPS and CDR format, in the exact size of the stamp. The smallest recommended line thickness is 0.2mms. If you are not much experienced in graphic software, we will make the graphic designs for you based on your own wishes (for a small surcharge).

The solder is a full-metal, solid construction, equipped with an industrial temperature control with feedback thanks to the inserted thermocouple inside the heating element. The burner has a thermal regulation from 40°C with the maximum temperature of up to 400°C, which can heat the golden brass stamp up to brown. The grip of the punch is covered by pleasant soft padding. The weight of the burner is just 1.1kg. The power cord is connected from the back in place where the display is. In case of need, it can also be disconnected when requested temperature achieved and can be used for burning without the power cord thanks to high thermal inertia of the heating element. The heating is relatively fast – approx. 2mins.

The stamp temperature is more than enough for leather stamping – for example for burning logo to leather wallets, belts, handbags, it is also ideal for wood stamping - e.g. pallets, wooden gift boxes (cigars, cigarettes etc.), it is suitable for plastics as well, an ideal for original sealing of all plastic bags PP/PVC/PE, also suitable for hot stamping. It is great for cardboard burning, possibly used for game marking and other use.

The supplied graphic design, for the stamp production have to be in vector graphics (curves) in *.AI, PDF, EPS and CDR format, in the exact size of the stamp. The smallest recommended line thickness is 0.2mms. If you are not much experienced in graphic software, we will make the graphic designs for you based on your own wishes (for a small surcharge).

| Weight | 1.5 kg |

Manufacturing instructions

The underlying documentation must always be provided in the following graphics file formats (*.ai .cdr .eps .svg .pdf), ideally in the exact size of the produced hologram. Mark the logo limits represented by the brass stamping block. It is important to add at least 2 millimetres on every side.

The underlying documentation must always be provided in the following graphics file formats (*.ai .cdr .eps .svg .pdf), ideally in the exact size of the produced hologram. Mark the logo limits represented by the brass stamping block. It is important to add at least 2 millimetres on every side.

The final manufacturing design should look like the picture below. The areas marked in black stand out and will stamp the design; the white ones will be cut (not stamping). The spacing of individual lines should correspond to the material the graphic design is to be stamped into. Even if the level of detail may be very high, it always depends on the material to be stamped (burnt). In case of wood, larger spacing of lines is recommended so they do not fuse together (0.5 mm at least). With leather, line spacing could be smaller, down to 0.25 mm, which really is not restricting at all – see the stamping specimen in our Product Gallery.

If you have no design to provide, you can have your graphics designed by our graphic designer. The artwork may be just a rough drawing or a text description. Our graphic designer’s imagination is not limited.

Related products

-

R6 Gas brand stamping device with your own logo design

from 263.188 € / pc.

R6 Gas brand stamping device with your own logo design

from 263.188 € / pc.

from 213.974 € without VATon order400420Product detail -

R8 Hot stamping press for thermal printing and stamping 420W - in-house design

from 558.602 € / pc.

R8 Hot stamping press for thermal printing and stamping 420W - in-house design

from 558.602 € / pc.

from 454.148 € without VATon order400474Product detail -

R9 Stamping plate with resettable numbers - 11 numbers, 70 mm

from 107.424 € / pc.

R9 Stamping plate with resettable numbers - 11 numbers, 70 mm

from 107.424 € / pc.

from 87.336 € without VATon order400477Product detail -

R10 Stamping plate with resettable numbers - 13 characters, 110 mm

from 118.166 € / pc.

R10 Stamping plate with resettable numbers - 13 characters, 110 mm

from 118.166 € / pc.

from 96.07 € without VATon order400478Product detail -

R4 Burning die for leather and plastic stamping with custom logo (design)

from 150.393 € / pc.

R4 Burning die for leather and plastic stamping with custom logo (design)

from 150.393 € / pc.

from 122.271 € without VATon order400304Product detail -

K3 Suitcase to store and transport lever-operated R3 stamp and R5 hot stamp - large

from 42.969 € / pc.

K3 Suitcase to store and transport lever-operated R3 stamp and R5 hot stamp - large

from 42.969 € / pc.

from 34.935 € without VATin Stock400306Product detail -

R13 Automatic pneumatic hot stamping press for hot stamping and burning with custom design

from 1503.933 € / pc.

R13 Automatic pneumatic hot stamping press for hot stamping and burning with custom design

from 1503.933 € / pc.

from 1222.71 € without VATon order400711Product detail