Product description

An affordable and high-quality professional hot stamping press capable of thermal printing offering both colour printing (gold printing) using hot stamping foils that we offer in great numbers, and colourless hot stamping (burning) that you know e.g. from diary covers (the year embossed in leather) or manufacturing logos burnt in wood. Unlike a manual marking iron, the press offers precise pressure distribution on all parts of the stamping iron in order to achieve an even result of stamping (or foil transfer). Also, the applied pressure is higher with manual stamping irons. The baseplate of the press has a measure (12x14 cm) that facilitates a very precise alignment. If you require high-precision alignment, you can screw the press to a work-top and install backstops that will ensure an identical outcome – there are countless options. The R8 hot stamping press is made of high-quality metal structure with virtually no plastic parts; it is made of genuine metal and aluminium (except of the temperature controller and rubber supports) so that long lifetime is guaranteed. The press head is located on a height-adjustable stand that allows to process items of up to 220 mm in height. The stamping plate (printing block) itself is made of brass. This brass block can be dismounted – hence, you can have multiple printing blocks that can be easily swapped on the press (when cold) – the stamping plate is fastened with a single screw and nut. Any stamping plate can be produced up to the maximum stamping surface of 100 x 80 mm. The level of detail might be very high; it always depends on the material that you want to stamp (burn). In case of wood, it is better to keep greater spacing between individual lines in order to avoid line merging (at least 0.5 mm). On leather, lines can be even 0.25 mm apart which no one can find restrictive at all – see printed samples in product images.

Example of the use: Colourless hot stamping (burning):

In leather – a logo hot stamped into leather wallets, belts, bags, covers, cases, Master’s thesis folders and diaries.

In wood – wooden gift cases – for cigars, cigarettes and other items, logos stamped into plank boards (working benches, wooden chopping boards...), decorative wooden plates, wooden tourist tokens and other flat wooden gift items.

In plastic – hot stamping of logos into plastic boxes and flat plastic surfaces, sealing all PP/PVC/PE bags, logos stamped in plexi-glass.

In paper – cardboard boxes (before assembly), gift bags from darker paper, cardboard textile tags and other.

Colour hot stamping (gold printing):

Always using hot stamping foils transferring the bottom foil layer onto a requested material at a maximum temperature of 120°C. This printing is known as gold printing, silver printing, hot stamping or thermal transfer. The foil is transferred only at the points where it connects to the hot contact surface of the stamping iron, with great precision; hence no colour is transferred outside of the stamping iron surface. Suitable materials must be selected for thermal transfer. Hot stamping works best on smooth high-substance paper (e.g. chalk-surfaced paper) with a specific finishing – e.g. glossy or matted lamination. Typically, such paper is used for packaging boxes - perfumes, eaux de toilette, creams, hair colours, alcohol gift boxes, cigarette packs, folders for Master’s theses and others. Thermal printing is used for all golden, silver or hologram decorated packaging boxes. It can also be used for gold-plated labels of wine, spirit and other bottles. Hot stamping foil would not work with standard paper without any plastic surface finishing - plastic coating (such as lamination) or local laser printing are a must.

As optional accessory, we offer the R8 press with a hot stamping foil reel-off holder that further facilitates the application of gold printing. The reel-off holder holds hot stamping foils of up to 80 mm in width.

Stamping iron size – discretionary up to max. 10x8 cm (width x height)

Power supply - 230V AC 420W

Temperature settings: 0-400 °C

Example of the use: Colourless hot stamping (burning):

In leather – a logo hot stamped into leather wallets, belts, bags, covers, cases, Master’s thesis folders and diaries.

In wood – wooden gift cases – for cigars, cigarettes and other items, logos stamped into plank boards (working benches, wooden chopping boards...), decorative wooden plates, wooden tourist tokens and other flat wooden gift items.

In plastic – hot stamping of logos into plastic boxes and flat plastic surfaces, sealing all PP/PVC/PE bags, logos stamped in plexi-glass.

In paper – cardboard boxes (before assembly), gift bags from darker paper, cardboard textile tags and other.

Colour hot stamping (gold printing):

Always using hot stamping foils transferring the bottom foil layer onto a requested material at a maximum temperature of 120°C. This printing is known as gold printing, silver printing, hot stamping or thermal transfer. The foil is transferred only at the points where it connects to the hot contact surface of the stamping iron, with great precision; hence no colour is transferred outside of the stamping iron surface. Suitable materials must be selected for thermal transfer. Hot stamping works best on smooth high-substance paper (e.g. chalk-surfaced paper) with a specific finishing – e.g. glossy or matted lamination. Typically, such paper is used for packaging boxes - perfumes, eaux de toilette, creams, hair colours, alcohol gift boxes, cigarette packs, folders for Master’s theses and others. Thermal printing is used for all golden, silver or hologram decorated packaging boxes. It can also be used for gold-plated labels of wine, spirit and other bottles. Hot stamping foil would not work with standard paper without any plastic surface finishing - plastic coating (such as lamination) or local laser printing are a must.

As optional accessory, we offer the R8 press with a hot stamping foil reel-off holder that further facilitates the application of gold printing. The reel-off holder holds hot stamping foils of up to 80 mm in width.

Stamping iron size – discretionary up to max. 10x8 cm (width x height)

Power supply - 230V AC 420W

Temperature settings: 0-400 °C

| Security level | medium |

| Weight | 6 kg |

Manufacturing instructions

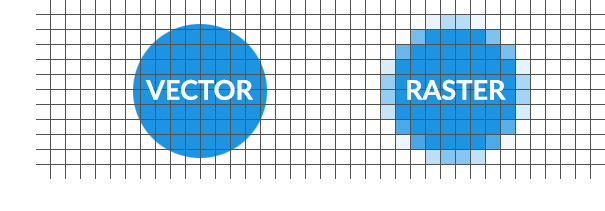

The underlying documentation must always be provided in the following graphics file formats (*.ai .cdr .eps .svg .pdf), ideally in the exact size of the produced hologram. Mark the logo limits represented by the brass stamping block. It is important to add at least 2 millimetres on every side.

The underlying documentation must always be provided in the following graphics file formats (*.ai .cdr .eps .svg .pdf), ideally in the exact size of the produced hologram. Mark the logo limits represented by the brass stamping block. It is important to add at least 2 millimetres on every side.

The final manufacturing design should look like the picture below. The areas marked in black stand out and will stamp the design; the white ones will be cut (not stamping). The spacing of individual lines should correspond to the material the graphic design is to be stamped into. Even if the level of detail may be very high, it always depends on the material to be stamped (burnt). In case of wood, larger spacing of lines is recommended so they do not fuse together (0.5 mm at least). With leather, line spacing could be smaller, down to 0.25 mm, which really is not restricting at all – see the stamping specimen in our Product Gallery.

If you have no design to provide, you can have your graphics designed by our graphic designer. The artwork may be just a rough drawing or a text description. Our graphic designer’s imagination is not limited.

Related products

-

R8.1 Hot stamping foil holder and reel stand to the R8 press 80 mm

from 96.681 € / pc.

R8.1 Hot stamping foil holder and reel stand to the R8 press 80 mm

from 96.681 € / pc.

from 78.603 € without VATin Stock400476Product detail -

R5 Hot stamping – leather, wood and cardboard burner, customer graphic design, 350W

from 456.55 € / pc.

R5 Hot stamping – leather, wood and cardboard burner, customer graphic design, 350W

from 456.55 € / pc.

from 371.179 € without VATon order400375Product detail -

R6 Gas brand stamping device with your own logo design

from 263.188 € / pc.

R6 Gas brand stamping device with your own logo design

from 263.188 € / pc.

from 213.974 € without VATon order400420Product detail -

R4 Burning die for leather and plastic stamping with custom logo (design)

from 150.393 € / pc.

R4 Burning die for leather and plastic stamping with custom logo (design)

from 150.393 € / pc.

from 122.271 € without VATon order400304Product detail -

H105 Hot Stamp Foil - V31 White

from 75.197 € / pc.

H105 Hot Stamp Foil - V31 White

from 75.197 € / pc.

from 61.135 € without VATin Stock400628Product detail -

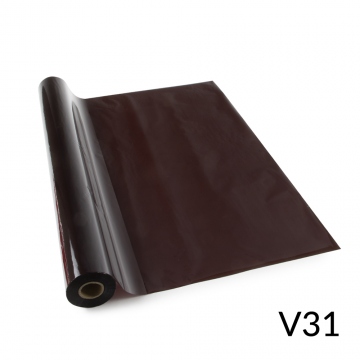

H105 Hot Stamp Foil - V31 Brown

from 48.341 € / pc.

H105 Hot Stamp Foil - V31 Brown

from 48.341 € / pc.

from 39.301 € without VATin Stock400629Product detail -

H105 Hot Stamp Foil - V32 Orange

from 37.598 € / pc.

H105 Hot Stamp Foil - V32 Orange

from 37.598 € / pc.

from 30.568 € without VATin transit 12.3.2026400630Product detail -

H105 Hot Stamp Foil - V33 Red

from 48.341 € / pc.

H105 Hot Stamp Foil - V33 Red

from 48.341 € / pc.

from 39.301 € without VATin Stock400631Product detail -

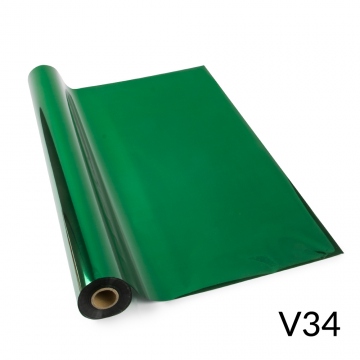

H105 Hot Stamp Foil - V34 Green

from 37.598 € / pc.

H105 Hot Stamp Foil - V34 Green

from 37.598 € / pc.

from 30.568 € without VATin Stock400632Product detail -

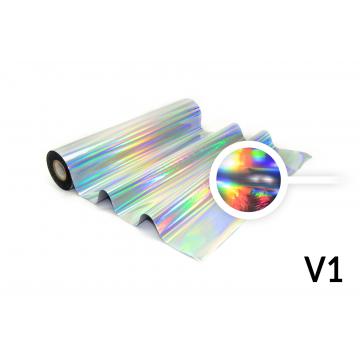

H105 Hot Stamping foil hologram silver, gloss without any pattern

from 37.598 € / roll

H105 Hot Stamping foil hologram silver, gloss without any pattern

from 37.598 € / roll

from 30.568 € without VATin Stock400316Product detail -

H105 Hot Stamping foil - V2 hologram silver, ellipse pattern, large, regularly arranged

from 37.598 € / roll

H105 Hot Stamping foil - V2 hologram silver, ellipse pattern, large, regularly arranged

from 37.598 € / roll

from 30.568 € without VATin Stock400294Product detail -

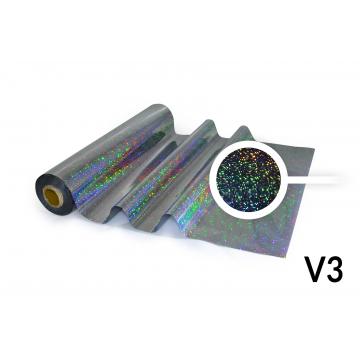

H105 Hot Stamping foil hologram silver, ellipse pattern, small, regularly arranged V3

from 37.598 € / roll

H105 Hot Stamping foil hologram silver, ellipse pattern, small, regularly arranged V3

from 37.598 € / roll

from 30.568 € without VATin Stock400295Product detail -

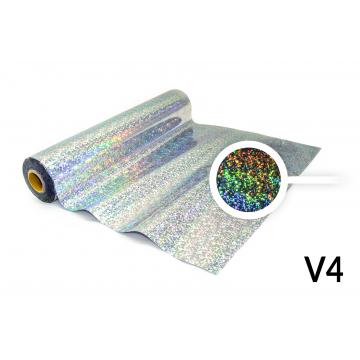

H105 Hot Stamping foil - V4 hologram silver, checked pattern

from 37.598 € / roll

H105 Hot Stamping foil - V4 hologram silver, checked pattern

from 37.598 € / roll

from 30.568 € without VATin Stock400312Product detail -

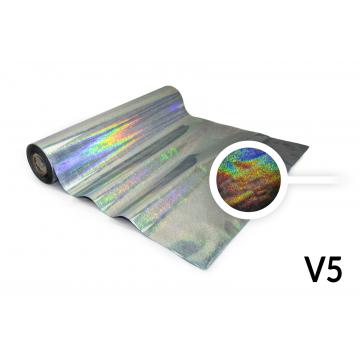

H105 Hot Stamping foil - V5 hologram silver, grain pattern

from 32.227 € / roll

H105 Hot Stamping foil - V5 hologram silver, grain pattern

from 32.227 € / roll

from 26.201 € without VATin Stock400315Product detail -

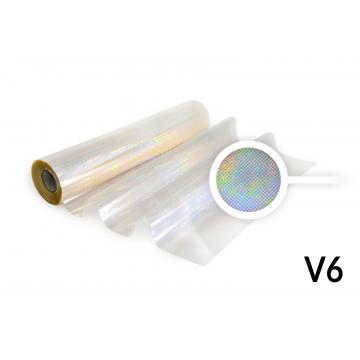

H105 Hot Stamping foil - V6 hologram transparent, grain pattern

from 53.712 € / roll

H105 Hot Stamping foil - V6 hologram transparent, grain pattern

from 53.712 € / roll

from 43.668 € without VATin Stock400296Product detail -

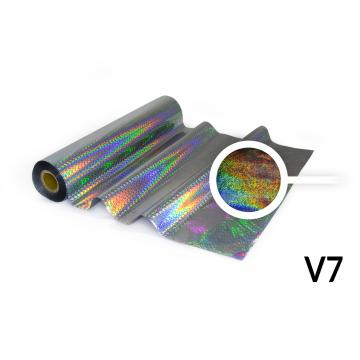

H105 Hot Stamping foil - V7 hologram silver, moving noise pattern

from 37.598 € / roll

H105 Hot Stamping foil - V7 hologram silver, moving noise pattern

from 37.598 € / roll

from 30.568 € without VATin Stock400297Product detail -

H105 Hot Stamping foil - V8 hologram silver, star pattern

from 37.598 € / roll

H105 Hot Stamping foil - V8 hologram silver, star pattern

from 37.598 € / roll

from 30.568 € without VATin Stock400298Product detail -

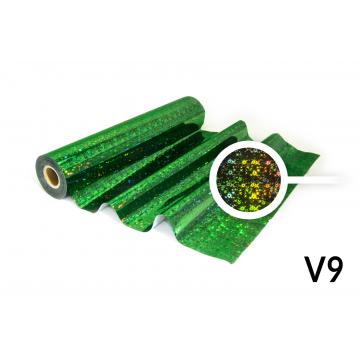

H105 Hot Stamping foil - V9 hologram green, star pattern

from 48.341 € / roll

H105 Hot Stamping foil - V9 hologram green, star pattern

from 48.341 € / roll

from 39.301 € without VATin Stock400299Product detail -

H105 Hot Stamping foil - V10 hologram blue, star pattern

from 48.341 € / roll

H105 Hot Stamping foil - V10 hologram blue, star pattern

from 48.341 € / roll

from 39.301 € without VATon request400300Product detail -

H105 Hot Stamping foil - V11 hologram gold, shards pattern

from 42.969 € / roll

H105 Hot Stamping foil - V11 hologram gold, shards pattern

from 42.969 € / roll

from 34.935 € without VATin Stock400307Product detail -

H105 Hot Stamping foil - V12 hologram burgundy red shards with wheels

from 48.341 € / roll

H105 Hot Stamping foil - V12 hologram burgundy red shards with wheels

from 48.341 € / roll

from 39.301 € without VATin Stock400308Product detail -

H105 Hot Stamping - V13 foil glossy gold

from 32.227 € / roll

H105 Hot Stamping - V13 foil glossy gold

from 32.227 € / roll

from 26.201 € without VATin Stock400309Product detail -

H105 Hot Stamping foil - V14 glossy bronze

from 32.227 € / roll

H105 Hot Stamping foil - V14 glossy bronze

from 32.227 € / roll

from 26.201 € without VATin transit400293Product detail -

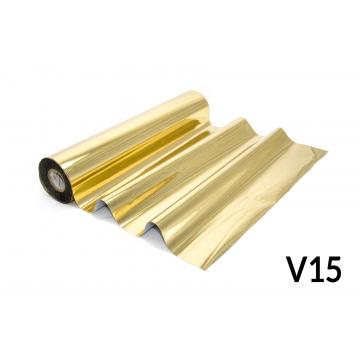

H105 Hot Stamping foil - V15 glossy brass

from 32.227 € / roll

H105 Hot Stamping foil - V15 glossy brass

from 32.227 € / roll

from 26.201 € without VATin Stock400105Product detail -

H105 Hot Stamping foil - V16 glossy black

from 32.227 € / roll

H105 Hot Stamping foil - V16 glossy black

from 32.227 € / roll

from 26.201 € without VATin Stock400313Product detail -

H105 Hot Stamping foil - V17 shiny blue with dots

from 32.227 € / roll

H105 Hot Stamping foil - V17 shiny blue with dots

from 32.227 € / roll

from 26.201 € without VATin Stock400314Product detail -

H105 Hot Stamping foil - V18 glossy red

from 32.227 € / roll

H105 Hot Stamping foil - V18 glossy red

from 32.227 € / roll

from 26.201 € without VATin Stock400310Product detail -

H105 Hot Stamping foil - V19 glossy silver

from 32.227 € / roll

H105 Hot Stamping foil - V19 glossy silver

from 32.227 € / roll

from 26.201 € without VATin Stock400311Product detail -

H105 Hot Stamping foil - V20 glossy light green

from 37.598 € / roll

H105 Hot Stamping foil - V20 glossy light green

from 37.598 € / roll

from 30.568 € without VATin Stock400317Product detail -

H105 Hot Stamping foil - V21 glossy orange – copper

from 37.598 € / roll

H105 Hot Stamping foil - V21 glossy orange – copper

from 37.598 € / roll

from 30.568 € without VATin Stock400318Product detail -

H105 Hot Stamping foil - V22 glossy dark gold

from 37.598 € / roll

H105 Hot Stamping foil - V22 glossy dark gold

from 37.598 € / roll

from 30.568 € without VATin Stock400319Product detail -

H105 Hot Stamping foil - V23 mixed colours on a silver base

from 45.655 € / roll

H105 Hot Stamping foil - V23 mixed colours on a silver base

from 45.655 € / roll

from 37.118 € without VATin Stock400349Product detail -

H105 Hot Stamping foil - V24 hologram gold with glitter

from 37.598 € / roll

H105 Hot Stamping foil - V24 hologram gold with glitter

from 37.598 € / roll

from 30.568 € without VATin Stock400350Product detail -

H105 Hot Stamping foil - V25 hologram chrome, shard pattern

from 37.598 € / roll

H105 Hot Stamping foil - V25 hologram chrome, shard pattern

from 37.598 € / roll

from 30.568 € without VATin Stock400351Product detail -

H105 Hot Stamping foil - V26 hologram gold 3D

from 37.598 € / roll

H105 Hot Stamping foil - V26 hologram gold 3D

from 37.598 € / roll

from 30.568 € without VATin Stock400352Product detail -

H105 Hot Stamping foil - V27 transparent hologram demetalised pattern shards

from 48.341 € / roll

H105 Hot Stamping foil - V27 transparent hologram demetalised pattern shards

from 48.341 € / roll

from 39.301 € without VATin Stock400353Product detail -

H105 Hot Stamping foil - V28 hologram diagonal silver

from 37.598 € / roll

H105 Hot Stamping foil - V28 hologram diagonal silver

from 37.598 € / roll

from 30.568 € without VATin Stock400354Product detail -

H105 Hot Stamping foil - V29 hologram transparent

from 48.341 € / roll

H105 Hot Stamping foil - V29 hologram transparent

from 48.341 € / roll

from 39.301 € without VATin Stock400292Product detail

R8 Hot stamping press for thermal printing and stamping 420W - in-house design

An affordable and high-quality professional hot stamping press capable of thermal printing offering both colour printing (gold printing) using hot stamping foils that we offer in great numbers, and colourless hot stamping (burning) that you know e.g. from diary covers (the year embossed in leather) or manufacturing logos burnt in wood.